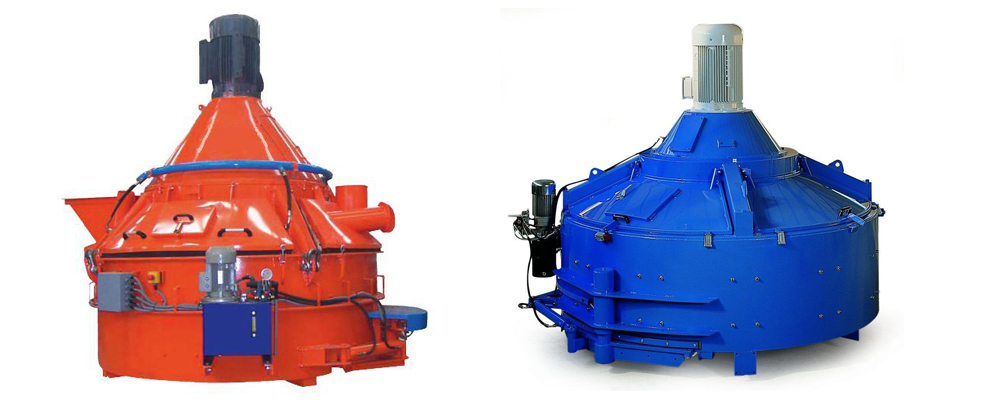

0,5 m3, 1 m3, 2 m3 mixers are produced.

| MB-P 0,33 | MB-P 0,5 | MB-P 1,0 | MB-9 2,0 | |

| Types | MB-P 0,33 m3 | MB-P 0,5 m3 | MB-P 1,0 m3 | MB-P 2,0 m3 |

| Dry Filling Capacity | 0,55 m3 | 0,75 m3 | 1,5 m3 | 3,0 m3 |

| Wet Concrete Capacity | 0,41 m3 | 0,625 m3 | 1,25 m3 | 2,5 m3 |

| Pressed Concrete Capacity | 0,33 m3 | 0,5 m3 | 1,0 m3 | 2,0 m3 |

| Engine Speed | 15 kW | 18,5 kW | 45 kW | 90 kW |

| Mixer Weight | 1.900 kg | 2.620 kg | 5.380 kg | 8.900 kg |

| Side Scraper | 1 | 1 | 1 | 1 |

| Base Scraper | - | - | 1 | 2 |

| Number of Arms x Number of Pallet at each Arm | 1x2 | 1x2 | 2x2 | 3x3 |

| Arm RPM/ Mixer RPM | 46/min-17/min | 46/min-16/min | 46/min-12/min | 33/min-9/min |

| Body | Welded, SANDED and Layered, Painted (Primer + Last Layer) | |||

| Paint | Thickness 120-200 micron | |||

| Reducer | MEKA/ COBRA (Italy) Planet Type Reducer | |||

| Engine Safety | Adjustable Thermic High Current Protection Relay SIEMENS (Germany) | |||

| Mixing Shaft/ Arms/ Scrapers | Strong shaft manufactured from forged steel / changeable arms manufactured from forged steel | |||

| Shaft and Arm Alignment | CNC robot machine with speed sensitiveness consisting solid quality control | |||

| Side Body Abrasionproof Elements | Exchangeable, ST52-10 mm thickness | |||

| Main Body Abrasionproof Elements | Exchangeable, 12 mm thickness HARDOX 450 (450 BH Hardness) | |||

| Mixing Arms and Scraper Abrasionproof Elements | 20 mm thickness exchangeable Ni Hard (600 Brinell Hardness) | |||

| Automated Lubrication | Automated lubrication system distributing oil from oil reservoir through gears | |||

| Discharge Cover | Rotating, hydraulic, emergency discharge pump | |||

| Number of Discharge Gates | 1 piece, 2nd discharge over option in some models | |||

| Discharge Control | Two switches with wide control gap over automation (opening time, standby time) | |||

Water Distribution |

Water discharge system on the shaft over nozzles with the help of gravity | |||

| Emergency Button | Lockable: CE Standards compatible | |||

| Dust Suppression | By-pass system connecting the mixer to cement weighting and Aggregate standby bunker | |||

| Maintenance Cover | With safety switch, wide, dust proof, safety grid observation cover | |||

| Cabling | Cabling was made previously to IP55 cable terminal junction box on the main body | |||

You can enlarge the image by clicking on it!